Within the structure of an electrical cabinet, hinges are often perceived as a quiet, secondary component. However, for cabinets whose doors are opened dozens of times daily, bear heavy weight, and endure harsh industrial environments, hinge performance directly dictates the long-term operational experience, structural integrity, and protection rating of the entire enclosure. They are not merely the “silent pivot point” for the door but the first line of engineering defense for the physical security of the power distribution system.

The Dynamic Portal of an Electrical Cabinet: Why Specialized Hinges are Indispensable

The door of an electrical cabinet is a high-frequency, dynamic system. Professional industrial hinges play multiple critical roles here; their failure leads directly to cascading issues:

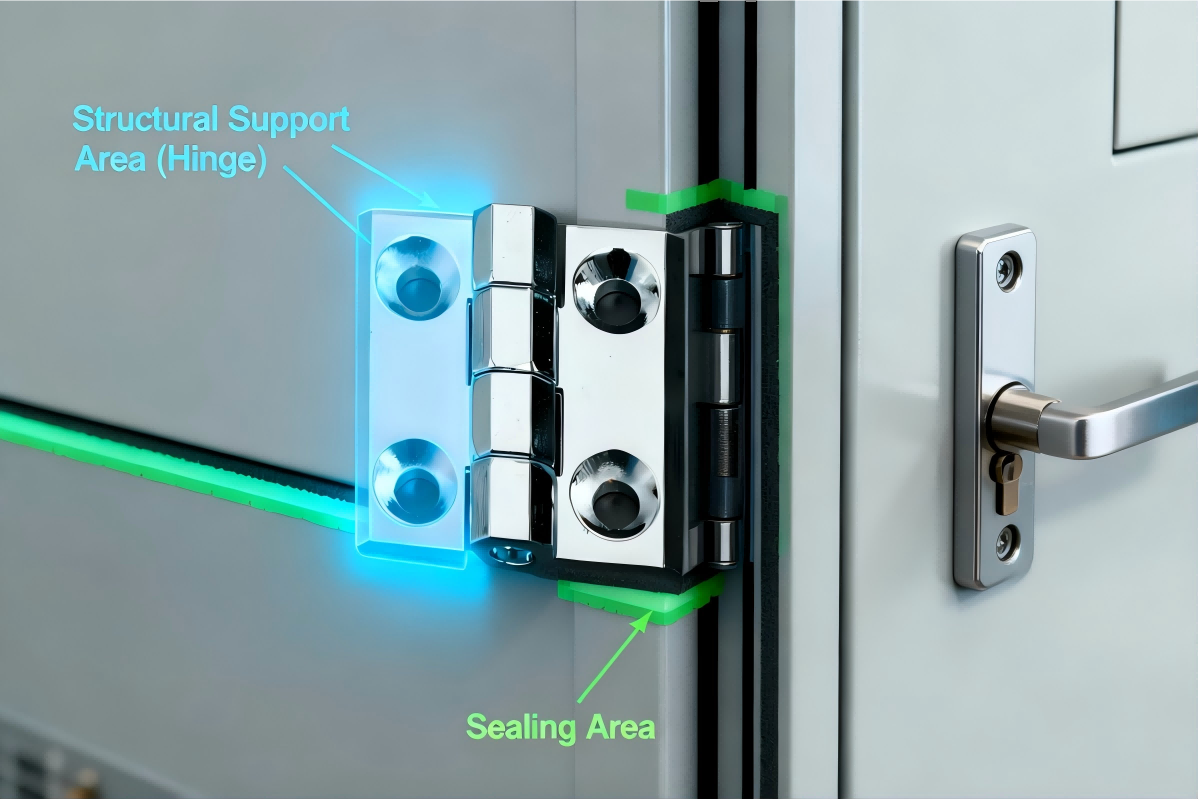

- Core Structural Support: Consistently and reliably supporting door panels that can weigh tens of kilograms, along with all mounted components (e.g., windows, locks, displays).

- Precise Motion Control: Ensuring smooth, consistent door opening (often to 110° or more) and closing without sagging, sticking, or noise, guaranteeing maintenance efficiency and safety.

- Foundation for Environmental Sealing: As a critical junction between the door and frame, their structural precision directly impacts gasket effectiveness, forming the basis for maintaining the cabinet’s IP rating (e.g., IP54, IP65) against dust and moisture.

- Guarantee of Safe Operation: Preventing doors from accidental detachment due to hinge fatigue or sudden failure, which could cause equipment damage or personnel hazard.

Beyond “Swiveling”: The Core Engineering Elements of a Professional Electrical Cabinet Hinge

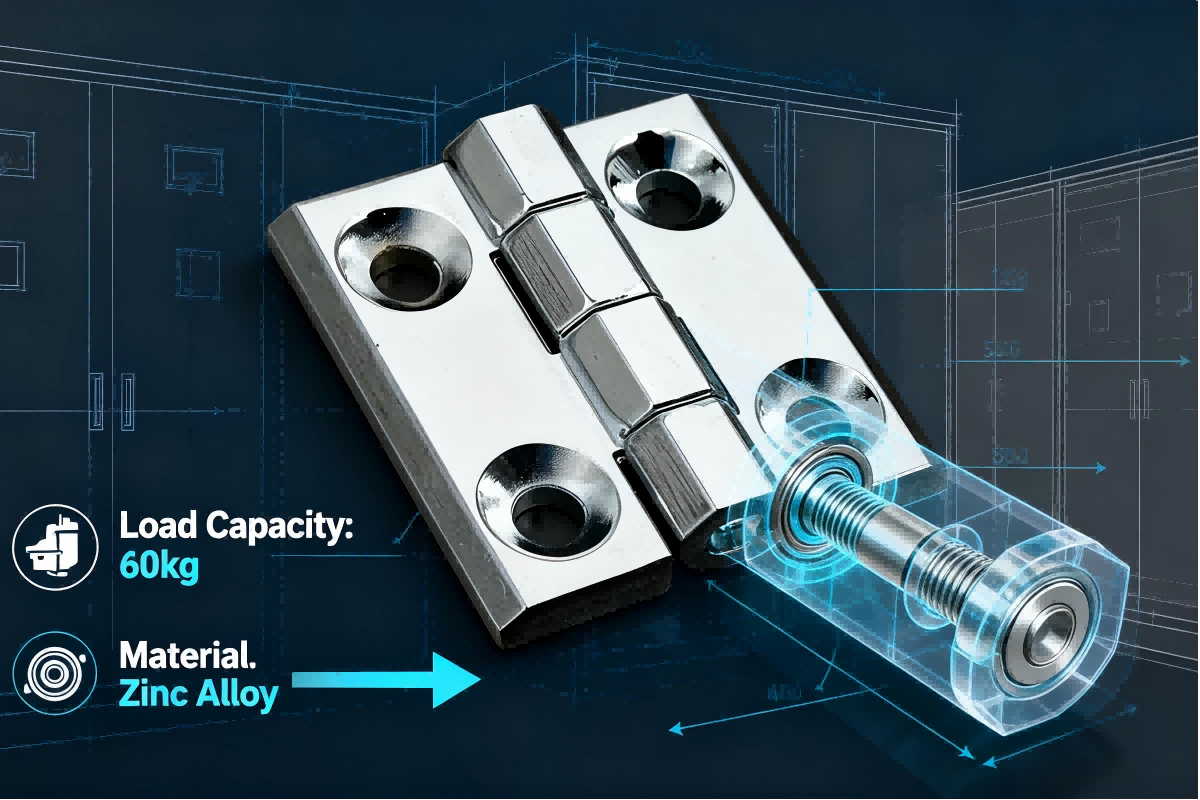

The value of a qualified electrical cabinet hinge is defined by a series of precisely measurable and verifiable engineering parameters:Material Science and Load Capacity: The main body typically uses high-strength cold-rolled steel stamped into form or zinc alloy die-casting for an optimal strength-to-weight ratio. Load capacity (e.g., 40kg, 60kg, 100kg per pair) and cycle life (often tested for tens of thousands of fault-free operations) are primary indicators, directly corresponding to door size and weight.

Precision Structure and Kinematic Design:

- Integrated Eccentric Adjustment: Allows 3D micro-adjustment of the door (vertical, lateral, depth) after installation to compensate for manufacturing and assembly tolerances, achieving perfect door-frame alignment and seal.

- Integrated Damping System: Optional built-in dampers enable soft, quiet, self-closing in the final 10-15°, eliminating slam noise and enhancing operational feel and safety.

- Removable Design: Certain models allow for quick door detachment/attachment without removing the hinge from the frame, greatly simplifying transport, installation, and maintenance.

Environmental Tolerance and Surface Engineering: Hinges must withstand the same harsh conditions as the cabinet. Surface treatments like zinc plating with passivation or high-quality powder coating provide long-term corrosion protection. For chemical, coastal, or outdoor applications, stainless steel hinges become essential.

Synergy with Locks: Building a Complete “Access Control System”

Hinges and locks are not isolated components. Together, they form a complete cabinet “Access Control System.” A hinge with insufficient rigidity or one that allows sagging creates misalignment between the door frame and the lock bolt. Even the most precise lock cannot function reliably under such conditions, leading to seal failure and premature lock wear. Therefore, selecting hinges that are compatible with your chosen lock brand/series and have the correct load rating is a prerequisite for an effective overall security solution. Professional manufacturers offer coordinated hardware solutions for hinges, locks, and latches, ensuring all components work together seamlessly in both design and performance.

How to Select the Right Hinge for Your Electrical Cabinet: A Selection Checklist

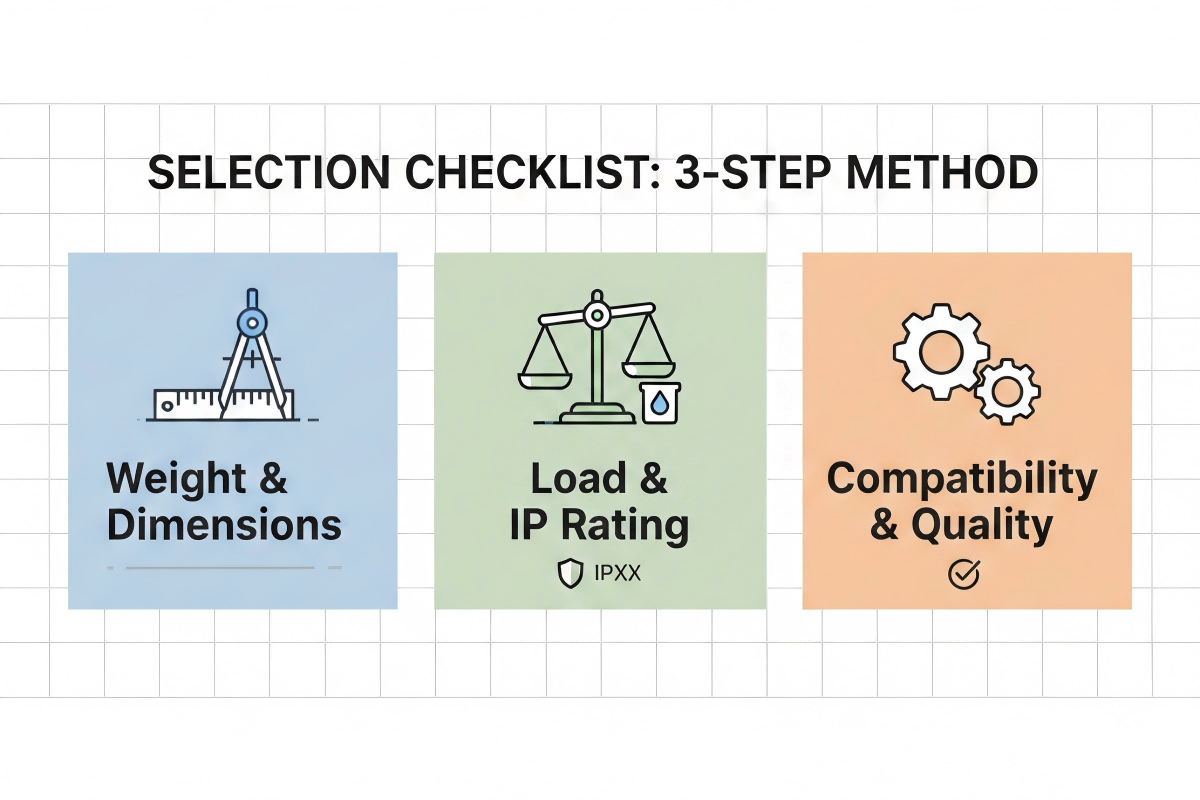

Navigate the product landscape systematically using this checklist:

- Step 1: Define Physical Parameters

Door panel dimensions, material, and total weight (including all accessories).

Required opening angle (typically 110°, 120°, or 180°).

Mounting type: Full overlay, half overlay (inset), or flush mount.

- Step 2: Define Performance Requirements

Load Rating: The hinge’s rated capacity should exceed the door’s actual weight by a factor of 1.5 or more for a safety margin.

Environmental Rating: Determine the required corrosion resistance (e.g., neutral salt spray test hours) and whether it needs to contribute to a specific IP rating.

Functional Needs: Is eccentric adjustment, damping, or quick-release functionality required?

- Step 3: Verify Compatibility and Quality

System Compatibility: Confirm the hinge is compatible with your chosen lock and cabinet frame structure.

Quality Indicators: Check for compliance with relevant industrial standards (e.g., fatigue testing) and review material certifications and finish specifications.

Lida’s Solution: Providing a Solid Rotational Foundation for Reliable Power Systems

At Lida, we view hinges as the core of a cabinet’s dynamic system. Our dedicated electrical cabinet hinge series is developed from a deep understanding of these engineering challenges:

- Engineering-Validated Design: From material selection to structural simulation, every hinge undergoes rigorous Finite Element Analysis (FEA) and physical load testing to ensure promised performance throughout its lifecycle.

- Complete Hardware Ecosystem: As a manufacturer of both high-quality locks and hinges, we ensure optimal synergy from the design stage. We offer pre-coordinated hardware kits to simplify your selection process and guarantee final assembly integrity.

- Deep Customization Capability: We can provide customized hinge solutions based on your unique cabinet design, color standards (RAL codes), or special load requirements, covering dimensions, finish, and functionality.

Conclusion

Selecting a professional electrical cabinet hinge is an investment in long-term smooth operation, structural stability, and security for your equipment. It operates without fanfare, yet reliably bears the weight of every critical access.When designing or upgrading your next-generation power distribution system, pay due attention to this “silent fulcrum.” Let Lida’s professional hinge and lock solutions together build a reliable portal that excels in everything from physical structure to access control.

Contact the Lida technical team today to request our industrial hinge catalog, technical white paper, or apply for sample testing. Find the most solid pivot point for your cabinet.

Post time: Jan-05-2026