In modern industrial design, security has long been associated with prominent, rugged hardware. Yet, a component that is quietly challenging this perception is being adopted by an increasing number of high-end devices: the Flush Mount Lock. It abandons the traditional protruding design, integrating complete locking functionality beneath a minimalist panel that sits perfectly level with the cabinet surface. This is not merely a cosmetic update; it represents a deeper design philosophy: the most effective security can be both invisible and elegant.

Part 1: The Power of Invisibility: The Core Design Philosophy

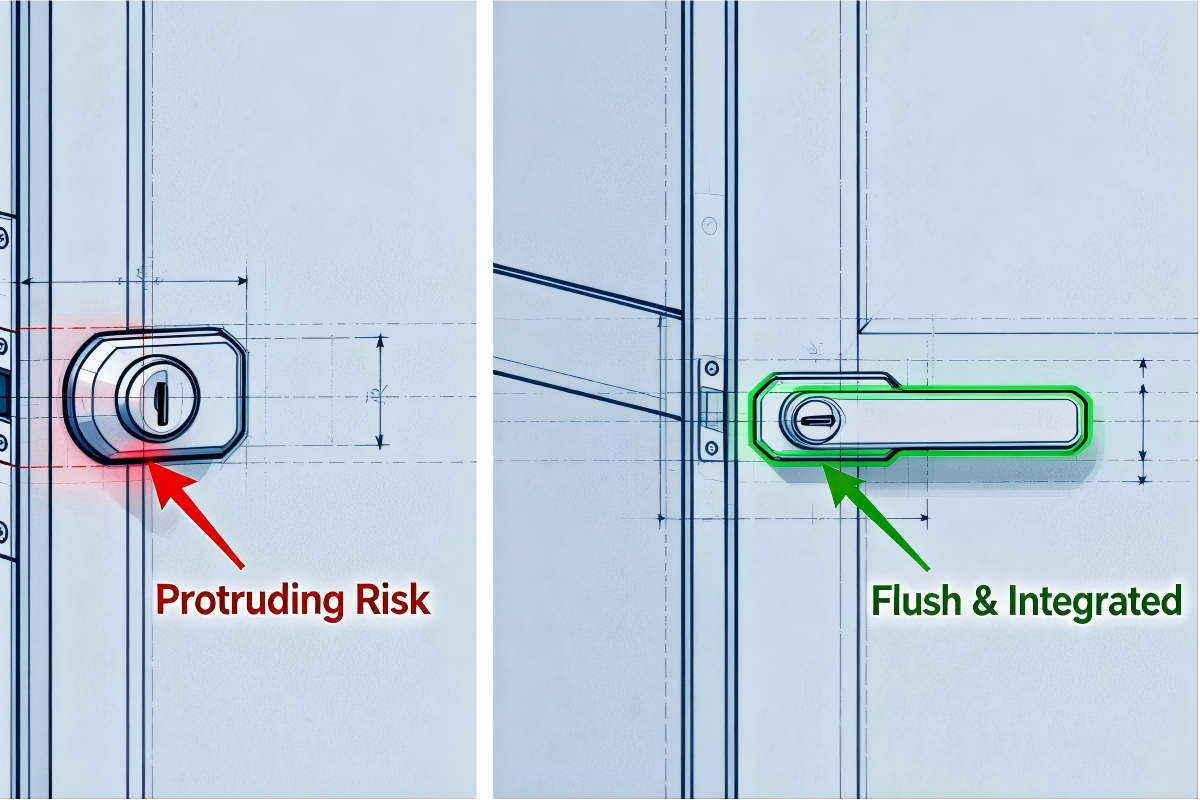

The breakthrough of the flush mount lock lies in its philosophy of “integration and concealment.” Through precision engineering, it houses the cylinder, actuator, and latch entirely within a low-profile housing. Once installed, only a nearly seamless panel or a discreet keyhole remains visible.

This design solves two inherent flaws of traditional protruding locks: First, it completely eliminates the risk of damage from impact during shipping, installation, and daily use, and prevents injury from snagging. Second, it grants the cabinet a complete, smooth visual plane, removing protruding edges that can collect dust and grime. The flush mount lock proves that security depends not on a bold physical presence, but on reliable internal mechanics and flawless external integration.

Part 2: Reimagined Advantages: Value Beyond Security

The value proposition of a flush mount lock is built on a matrix of security, durability, aesthetics, and user experience, offering a comprehensive solution:

Superior Environmental Resistance and Physical Protection: Its flush nature provides inherent better defense against dust and water ingress, more easily achieving higher IP ratings. The solid panel distributes external force evenly, offering significantly improved impact and vandalism resistance. This makes it ideal for unattended outdoor equipment, public infrastructure, and clean environments like laboratories.

Enabling Modern Industrial Aesthetics: As design evolves beyond “form follows function” toward “function integrated with form,” the hidden design of flush mount locks allows cabinets to maintain pure geometric lines and unified color textures. They are perfectly suited for applications with stringent aesthetic demands—such as data centers, high-end medical devices, and smart office furniture—directly enhancing the end product’s brand value and technological appeal.

Optimized User Experience and Operational Efficiency: The smooth surface is easy to clean and prevents clothing or cables from snagging. Many high-end flush mount locks incorporate ergonomic features like soft-close mechanisms, status indicators, or integrated pull-out handles, ensuring every operation is smooth and definitive while maintaining a clean appearance.

Part 3: Application Innovation: Industries Being Redefined

The use of flush mount locks has moved from niche to mainstream, becoming the preferred choice for premium equipment in these sectors:

- High-End IT & Data Centers: Server racks, network switching nodes, core storage devices, ensuring security while maintaining a clean, professional facility aesthetic.

- Precision Instruments & MedTech: Medical imaging equipment, laboratory analyzers, semiconductor fabrication tool cabinets, meeting demands for cleanliness, easy sterilization, and visual appeal.

- Public Transport & Smart Mobility: EV charging stations, rail transit control boxes, shared service kiosks, withstanding harsh outdoor conditions while elevating public space design.

- Modern Office & Commercial Spaces: Intelligent storage systems, high-end AV control consoles, interactive digital signage, achieving seamless integration of security and spatial design.

- Advanced Industrial Automation: Peripheral guarding for robot control units and precision assembly workstations, providing reliable, unobtrusive access control in complex factory settings.

Part 4: Selecting a Flush Mount Lock: Critical Dimensions to Consider

Choosing the right flush mount lock requires careful examination of several engineering details:

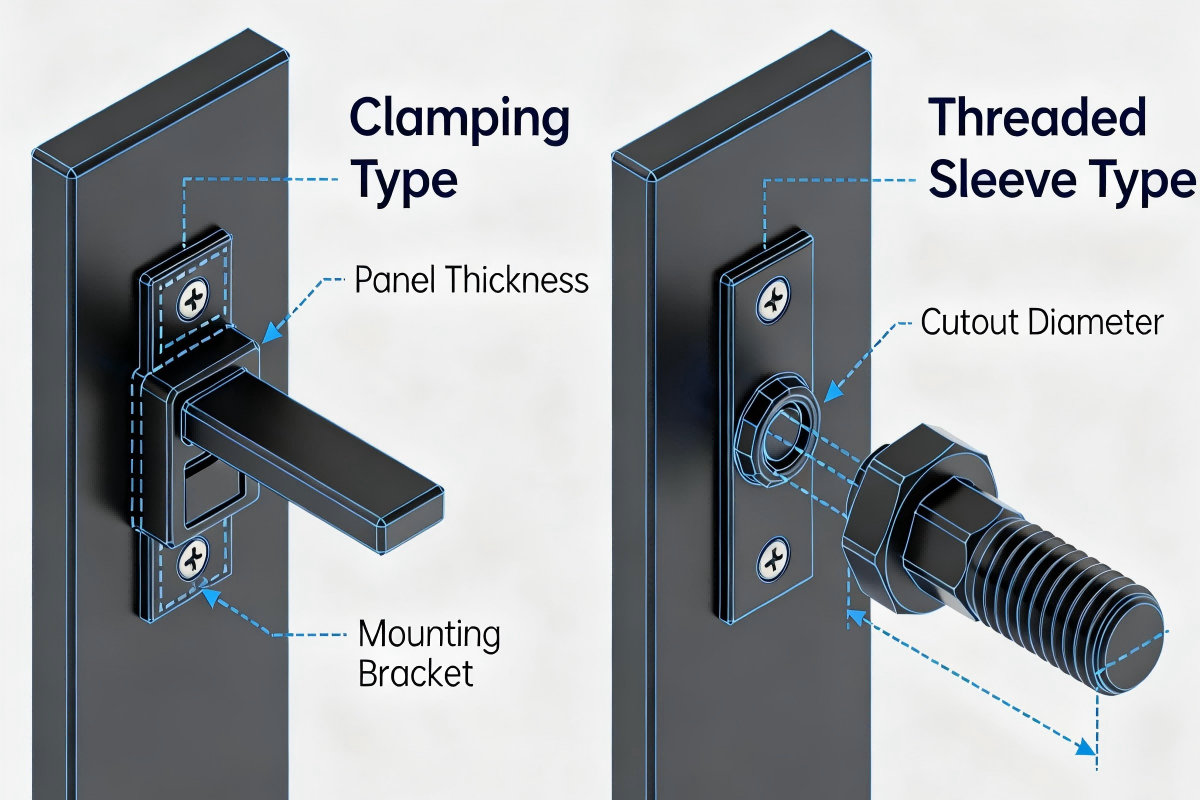

- Mounting Structure and Panel Compatibility: This is paramount. Determine if a “clamp-style” mount (for doors within a specific thickness range) or a “threaded bushing” mount (for thicker panels) is needed. Precisely measure door thickness, cutout dimensions, and tooling requirements.

- Material, Finish, and Protection Rating: The housing material (e.g., stainless steel, aluminum) and surface finish (anodizing, powder coating) determine corrosion resistance and color matching. Verify the IP rating (e.g., IP65, IP67) matches the deployment environment.

- Cylinder Security and Actuation Mechanism: Select the cylinder grade based on security needs. Also, understand if the mechanism is purely mechanical, electro-mechanical (with signal feedback), or supports electronic access (RFID/code), enabling integration into broader management systems.

- Ergonomic Details: Despite a simple appearance, the devil is in the details. Check key insertion smoothness, required turning torque, and the presence of aiding features like grip grooves, all of which impact the end-user’s daily experience.

Part 5: Lida’s Flush Mount Lock Solutions: Mastering the Art of Concealment

At Lida, we approach the flush mount lock as “discreet precision engineering.” Our development focuses on solving the complex challenges behind concealment:

- Deep Structural Innovation: We engineer innovative gear or linkage systems within an ultra-low-profile space to deliver latch strength and durability equal to or greater than traditional locks, ensuring “invisibility” never comes at the cost of performance.

- Custom Integration Services: We offer extensive options for color, texture, and logo engraving, ensuring the lock becomes a harmonious, integrated element of your product’s design language, not an added-on component.

- Rigorous Environmental Validation: Every flush mount lock undergoes cycle testing, salt spray corrosion testing, and dust/water ingress testing, guaranteeing reliable performance throughout its promised service life—even when out of sight.

Conclusion

The flush mount lock represents a mature design confidence: true security needs no announcement, and superior engineering can remain hidden. It marks the evolution of industrial hardware from a mere “functional part” to an “integrated design element.”

When your product design seeks the unity of internal reliability and external simplicity, Lida’s Flush Mount Lock solutions provide the key. It guards without intruding; it is essential, yet knows how to remain unseen.

Contact the Lida team to discover how our Flush Mount Lock series can bring the power of invisible security to your next-generation designs.

Post time: Dec-31-2025