For panel builders, system integrators, and OEMs, specifying an enclosure with an IP66 rating is a commitment to protecting sensitive electronics from dust and powerful water jets. However, a critical misconception can undermine this commitment: the belief that the IP rating is a property of the enclosure shell alone. In reality, achieving and maintaining IP66 integrity is a system performance challenge, where the seemingly minor component—the lock—plays an outsized role as the critical load-bearing interface. This article shifts the perspective from viewing locks as simple fasteners to understanding them as essential elements in a pressure management system, and provides a framework for procurement specialists and engineers to make informed decisions.

Outline

- The System Challenge: Why Locks are the Linchpin in IP66 Sealing - Explains the mechanical principles of IP sealing and identifies common failure points introduced by inadequate locking hardware.

- Engineering the Solution: Key Design Features of a System-Optimized Lock - Details the specific attributes a lock must possess to support, rather than compromise, the sealing system.

- Strategic Sourcing for Reliability: A Guide for Bulk Buyers and OEMs - Translates technical requirements into a practical checklist for evaluating suppliers and specifying components for batch orders.

- Conclusion: Partnering for Performance - Summarizes the integral role of specialized hardware and the value of expert partnership.

1. The System Challenge: Why Locks are the Linchpin in IP66 Sealing

An IP66 seal is achieved when a compressible gasket, trapped between the door and the frame, is subjected to uniform and sufficient pressure around its entire perimeter. The primary mechanical function of the lock is not just to secure the door, but to generate and maintain this precise clamping force.

The most common failure points stem from poor force management:

- Uneven Pressure Distribution: A single-point cam lock or handle lock exerts concentrated force directly opposite the strike point. This can cause subtle panel deflection, leaving areas of the gasket—particularly at the corners—under-compressed and creating paths for ingress.

- Insufficient or Inconsistent Force: A lock must provide enough torque to compress the gasket fully and maintain this compression despite temperature cycling and gasket relaxation. Under-specified locks from a generic vendor may work initially but fail over time.

- Structural Flex and Corrosion: The lock itself and the door material around its mounting point must not deform under load. Furthermore, in harsh environments, corrosion of lock components can lead to seizure or reduced clamping force, breaking the seal. This makes the choice of manufacturer and material critical for long-term performance.

2. Engineering the Solution: Key Design Features of a System-Optimized Lock

Leading industrial lock manufacturers design products with the entire enclosure system in mind. When evaluating a supplier for a critical application, consider these non-negotiable engineering features:

- Force Distribution Design: The most effective solution for large doors is a multi-point linkage lock system. By activating multiple latch points along the door edge, it creates a balanced, uniform clamping force, ensuring consistent gasket compression from the center to the corners. This systemic approach is far superior to relying on a single point of pressure.

- Rigid Construction and Precision Mounting: The lock must be a stable anchor point. High-quality flush mount locks and heavy-duty handle locks are engineered with reinforced bodies to resist torsional flex when tightened. As an experienced OEM/ODM partner, a proficient factory can also provide custom mounting solutions or precise templates to ensure the lock integrates perfectly with the door’s gasket channel, a vital consideration for high-volume production.

- Material Integrity for Lifetime Performance: While the lock body is not the primary seal, its durability guarantees the seal’s persistence. Stainless steel locks or those with advanced corrosion-resistant coatings prevent degradation from humidity, chemicals, and salt spray. This preserves the designed clamping force for the enclosure’s operational life, a key factor in calculating Total Cost of Ownership (TCO) for end-user distributors and their clients.

3. Strategic Sourcing for Reliability: A Guide for Bulk Buyers and OEMs

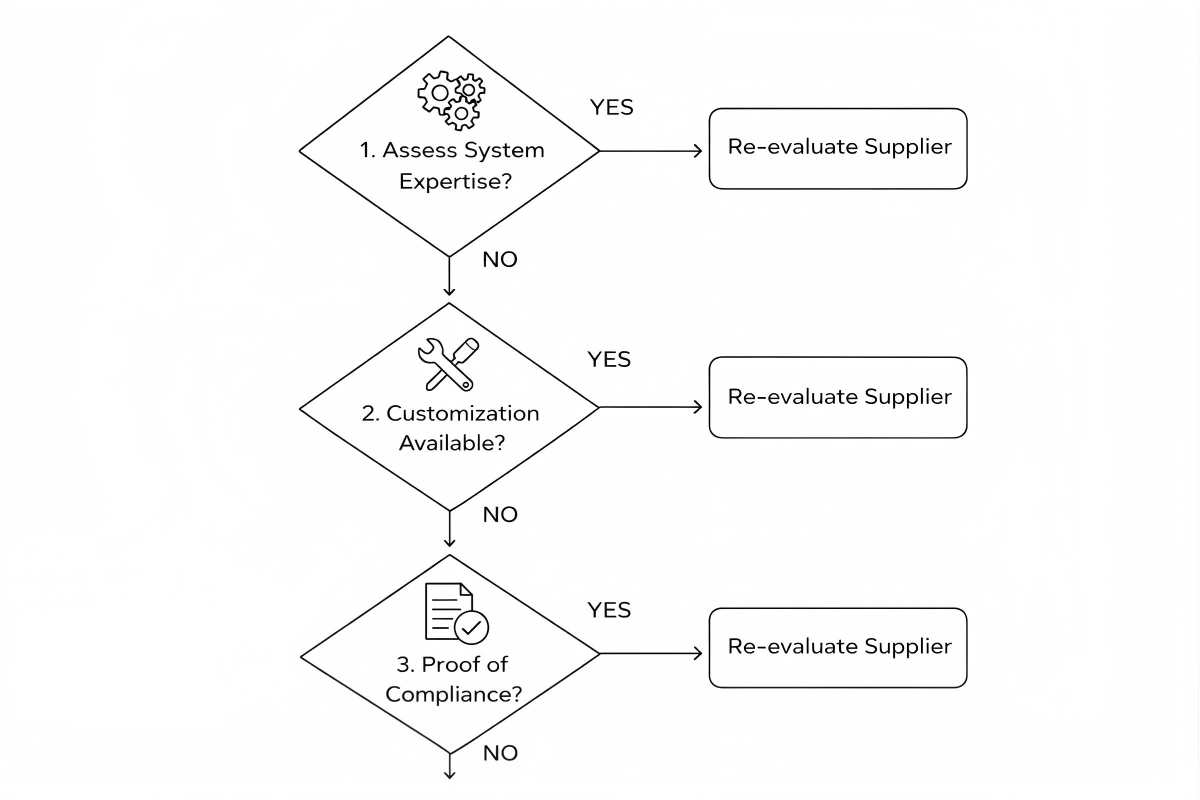

For procurement managers overseeing bulk or batch order purchasing, technical specifications must align with commercial strategy. Use this checklist to qualify your hardware supplier:

- Audit for System Expertise: Move beyond catalogs. Does the supplier or manufacturer demonstrate understanding of gasket compression, force distribution, and real-world panel deflection? Request white papers or application notes on sealing.

- Evaluate True Customization Capability: Standard items may not suffice. Can the vendor accommodate custom modifications? This includes non-standard mounting hole patterns, specific spindle lengths for thicker doors, or tailored finishes to match other OEM components. Clarify MOQ requirements for such customized projects early.

- Demand Material and Test Verification: Require proof. Any competent factory should provide material certifications (e.g., for 304/316 stainless steel) and standardized test reports for salt spray resistance (e.g., ASTM B117) to validate environmental claims.

Conclusion

4. Partnering for Performance

Specifying hardware for an IP66 enclosure is an exercise in systems engineering. The lock is not an accessory; it is the critical component that activates and sustains the protective seal. Choosing a supplier who grasps this principle is as important as the technical specifications themselves.

At Lida Lock, we operate with this systems-first philosophy. As a dedicated manufacturer and collaborative ODM partner, we provide more than components—we deliver engineered interfaces that ensure the designed performance of your enclosure system. From supporting wholesale distributors with reliable standard stock to developing fully customized locking solutions for global OEM projects, our focus is on enabling your success in creating robust, reliable industrial equipment.

Ready to specify locks that secure more than just the door?

Contact our engineering and sales team today to discuss your IP-rated enclosure challenges, request product validation data, or initiate a consultation for a custom solution. Let’s build reliability into your design.

Post time: Jan-22-2026